Beyond OEM: How Aftermarket MAFs Can Impact Fueling and Performance

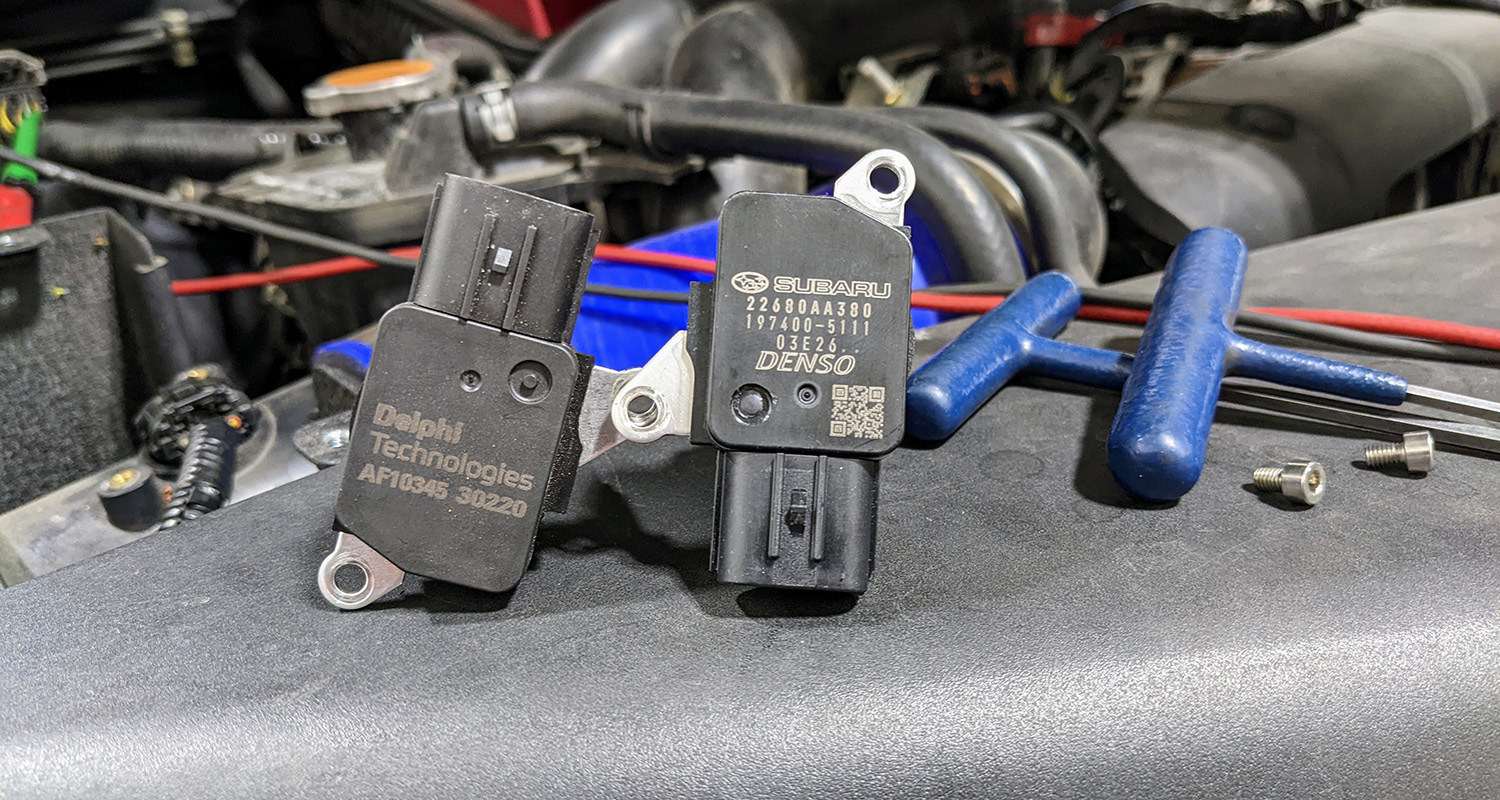

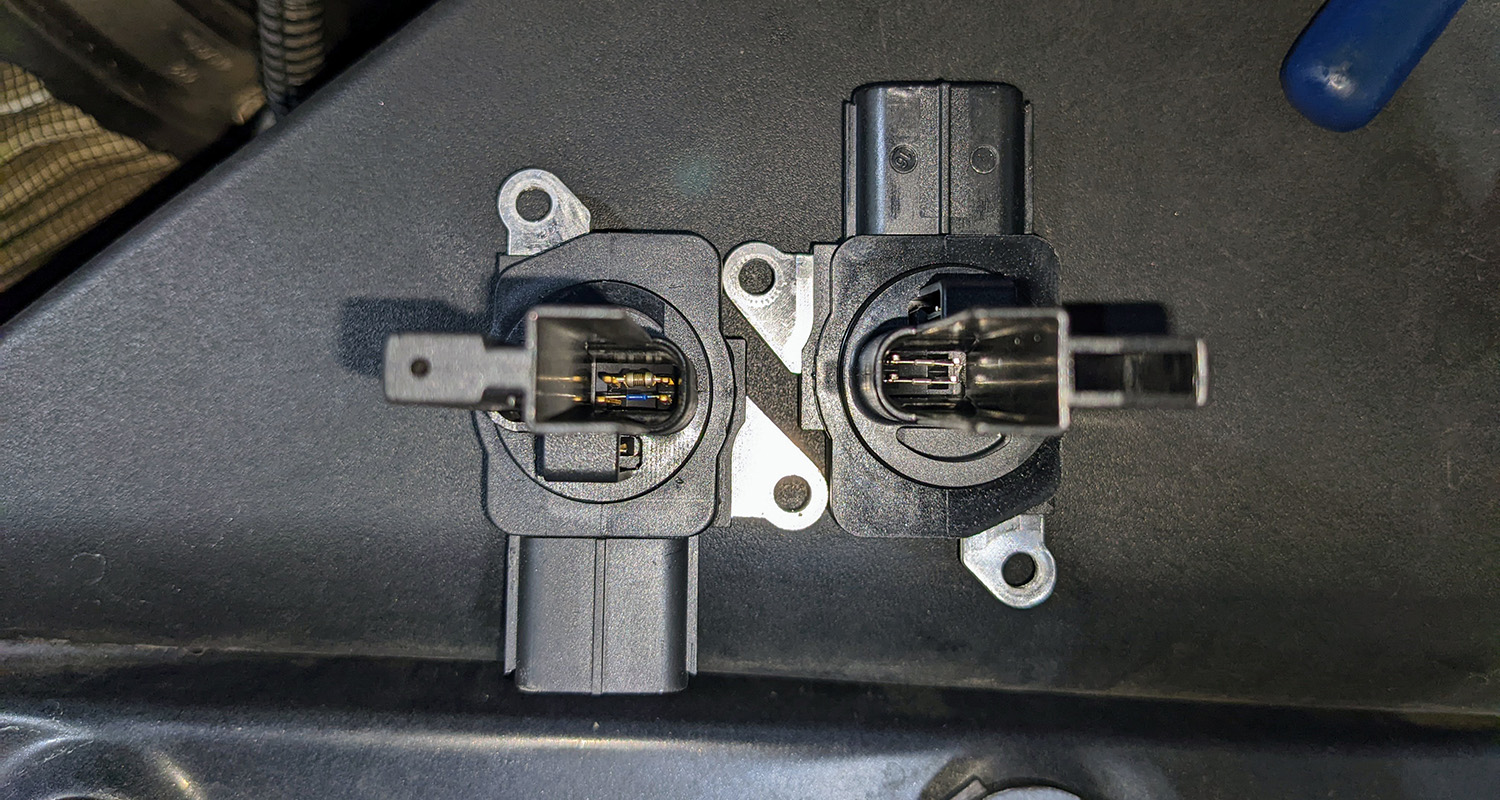

I recently had the opportunity to do some back-to-back testing with mass airflow (MAF) sensors. The car in question was a 2012 WRX that I had previously tuned. The customer had replaced the MAF with an aftermarket Delphi and wanted us to see if everything was functioning as it should.

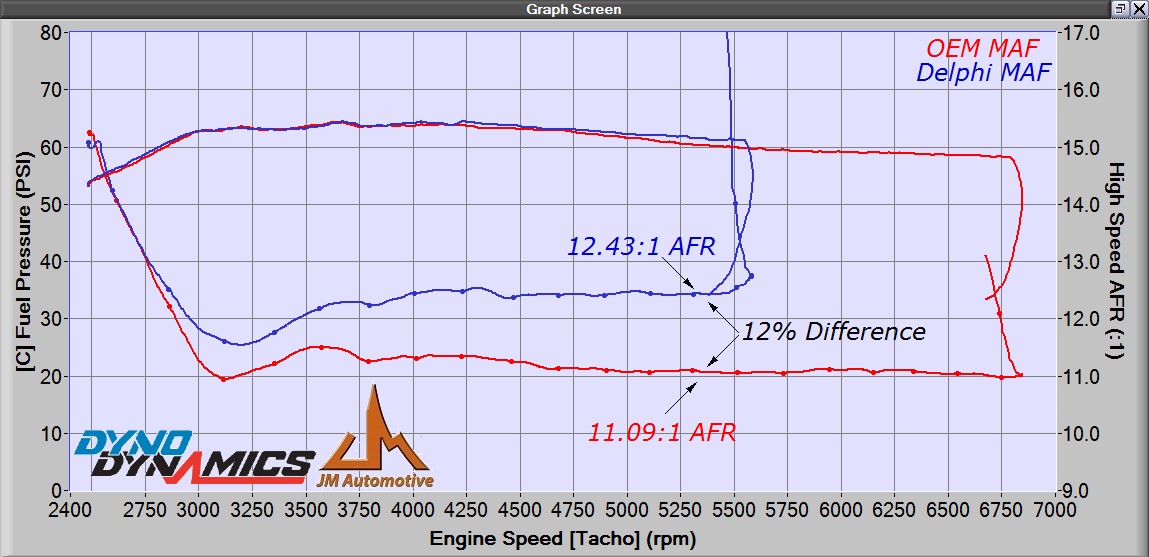

I put the car on the dyno and did some pulls. Immediately, I could see that the air-fuel ratio (AFR) was much leaner than when I originally tuned it. I put a new OEM MAF in, and fueling was back where it was originally. The tune was not changed between the pulls, just the MAF sensors.

Above is the dyno graph of the pulls. The red lines are for the OEM MAF, and the blue lines are for the Delphi MAF. You can see just how much leaner the Delphi MAF made the car run compared to the OEM MAF. In fact, the Delphi MAF was causing the car to run at 12.43 AFR at 5300rpm, whereas the OEM MAF was running at 11.09. That’s a 12% difference and a dangerously lean AFR for a Subaru on pump gas. It was so lean that right before I let off, the ECU picked up -2.8deg of fine knock learned, and the DAM dropped from 1 to 0. When looking at fuel pressure, you can see that they are the same, so that takes away any difference that could be caused by different fuel pressure.

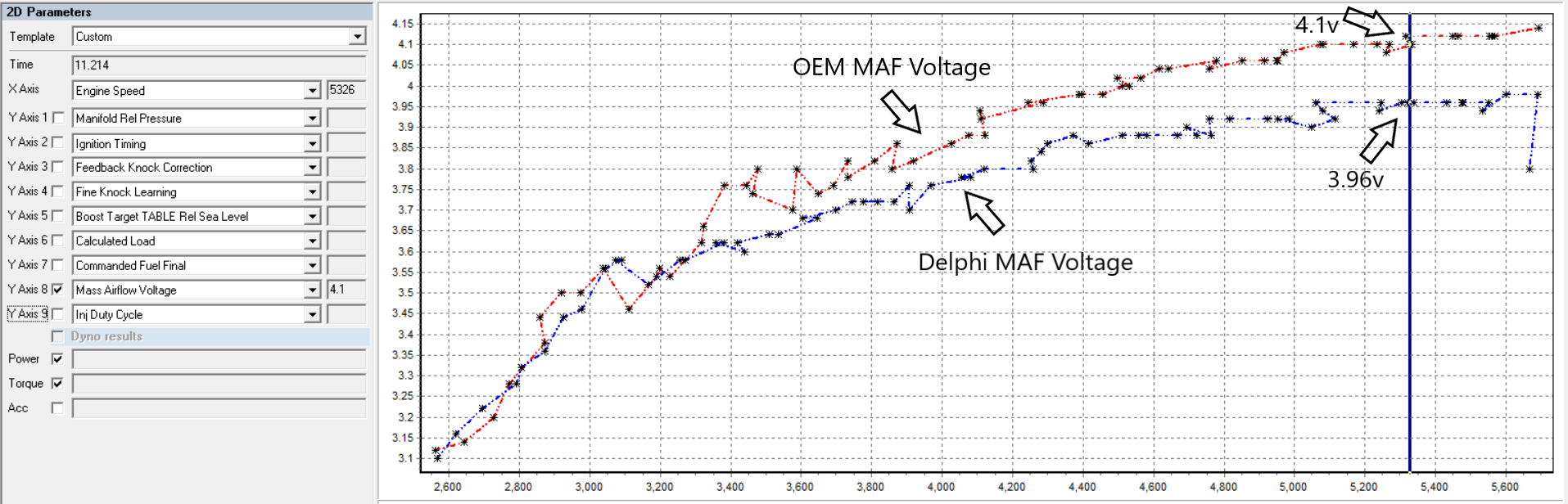

Above are the data logs from the pulls. Again, red is for OEM, and blue is for Delphi. The voltages are very similar until about 3200rpm, and as RPM increases, the Delphi starts reading less and less voltage compared to the OEM sensor. At 5300rpm, the OEM sensor is reading 4.1V while the Delphi is reading 3.96V. While that doesn’t seem like a big difference, if you look at the grams per second calculated by the ECU at that RPM, you will see that they are 10-12% off, almost the same amount that the AFR is off. The OEM MAF is reporting about 255 grams per second, and the Delphi MAF is reporting about 225 grams per second at 5300rpm. The grams per second are what the ECU uses to calculate how much air is entering the engine and thus how much fuel to inject. You can see how critical the MAF is in the ECU’s calculations.

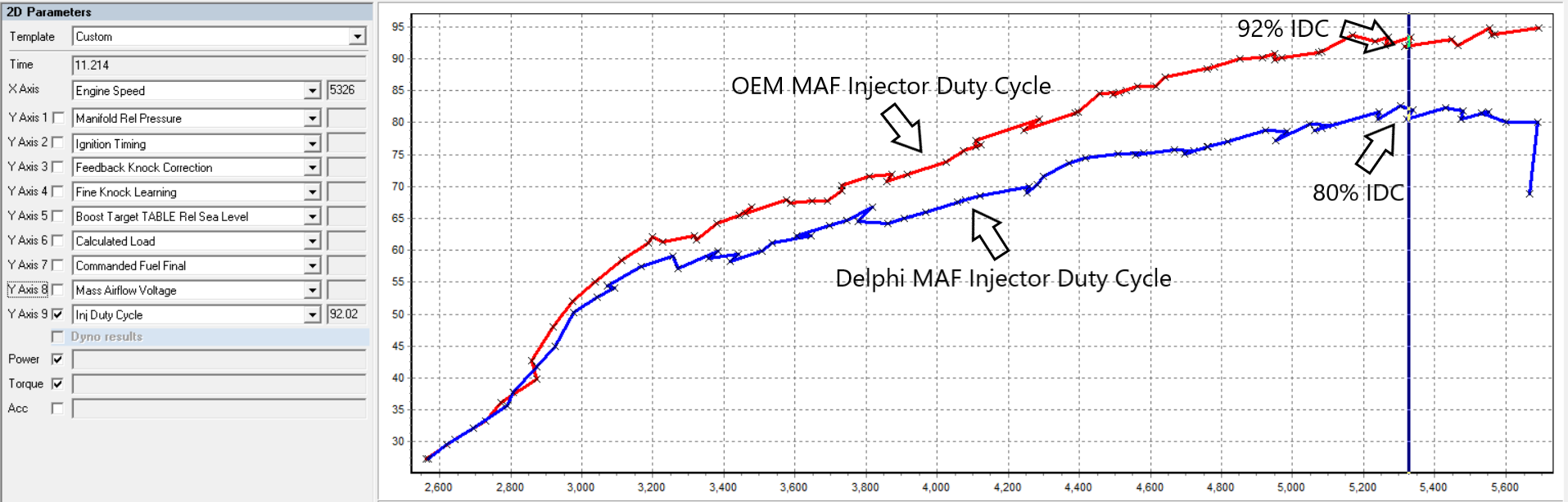

Here is another data log with the injector duty cycle. Again, you can see just how much the fueling changes with slight differences in MAF voltage readings. You can see the same trend as the MAF voltage log. The injector duty cycle starts out very close until about 3200rpm and slowly has a bigger and bigger discrepancy until the end of the pull.

All of this information points to the fact that not all sensors are the same. This is the reason we always recommend using an OEM MAF because reading just slightly off can cause significant changes in fueling. Having a clean MAF is also essential when you get your car tuned. If it’s dirty when we tune it, and you clean it later, it can have the same effect on changing the reported voltage to the ECU, throwing off your fueling.

Why MAFs Matter: Understanding the Role of Mass Airflow Sensors in Your Engine

In conclusion, our testing showed that aftermarket MAFs can significantly impact fueling and performance in your car. While it may be tempting to try a cheaper alternative, using an OEM MAF is crucial for reliable and consistent performance. Additionally, keeping your MAF clean and well-maintained is essential for accurate readings and optimal engine performance. By prioritizing the quality and condition of your MAF, you can ensure that your car runs smoothly and efficiently for years to come.